The Story of the

Holton Heath, Dorset, UK

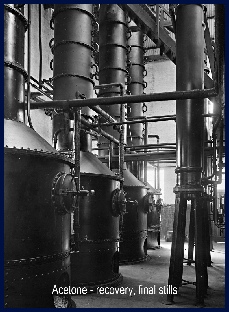

Manufacture of Acetone

Acetone (an organic solvent) was needed in large amounts in the manufacture of cordite in the WW1 period by assisting in the incorporation of nitroglycerine with guncotton and the other minor additives.

There was soon to be a world shortage of acetone and plans had to be rapidly made to find alternative methods of production to satisfy the needs of the naval propellant supply.

The science of biochemistry was to come to the fore and the work researched by Chaim Weizmann at Manchester University on the production of butyl alcohol and acetone and offered to the Government at the beginning of WW1, was brought to the notice of Winston Churchill in 1916, then Minister of Munitions.

Weizmann was asked to scale up his process from small laboratory samples to an industrial size.

He took advantage of the experience of the brewing industry and at Nicholson’s Gin Factory in Bromley managed to produce half ton lots after a period of 6 months and with this encouragement a large amount of acetone was eventually produced at breweries at many sites round the country using various carbohydrate fuels (potatoes, artichokes, maize) with the appropriate yeasts, and in other countries use was made of rice in India, wheat in Canada and even seaweed in California where these materials were plentiful.

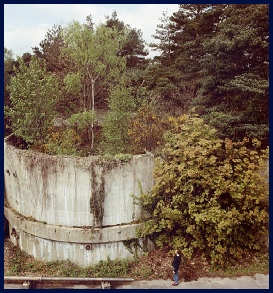

A special plant was also built at the instigation of Winston Churchill at the Royal Naval Cordite Factory in 1917 relying on maize imported from the USA – being the largest building constructed on the site. The maize was cooked in a boiler to form a liquor to which a specific yeast was added. The liquor was transferred to eight large fermentation vats contained within large concrete cylinders measuring about 11.5m in diameter. The fermentation process was maintained at a suitable temperature with steam heating and water cooling pipes. After fermentation the liquid was passed to a distillation plant to separate out the acetone. However by mid 1917 the supply of maize became very short due to the action of German submarines in the Atlantic and alternative materials again were needed.

In the log books of Lockyer’s Middle School, Corfe Mullen in Dorset it was noted by the head teacher:

By John England

15th October 1917 – “At the request of the Managers I am taking some of the older children up to ‘The Knoll’ to gather horse chestnuts which are to be sent to the munition works.”

On 10th October a directive arrived at all the local schools headed: Holton Heath Naval Cordite Factory, Collection of Acorns -

On 19th October the minute book reported: “H J Mills, Correspondent, visited and informed me the school was to be closed on account of the prevalence of whooping cough among the children. In response to the suggestion on Circular C L 187 from the Dorset Education Committee, many of the older children have volunteered to collect acorns and horse chestnuts for the R N C F at Holton Heath”

A short note also appeared in the local weekly paper, the East Dorset Herald, on 25th October headed: Acorns Urgently Needed - “The Superintendent, R N Cordite Factory Holton Heath, near Wareham, is prepared to pay at the rate of 1/3d per bushel for good Acorns in lots of 50 bushels and over, delivered at nearest railway station in the County of Dorset. A limited number of sacks are available and can be lent on application being made to the Superintendent, R N Cordite Factory who must be informed directly the collection is completed in order that forwarding instructions may be given”.

One result of this was the collection of ‘four tons of acorns for munition making’ at Poole Secondary School. This was reported in the paper on 27th December included in the report of the Speech Day and Prize-giving.

One result of this was the collection of ‘four tons of acorns for munition making’ at Poole Secondary School. This was reported in the paper on 27th December included in the report of the Speech Day and Prize-

Decommissioning

The Acetone plant eventually was decommissioned in 1927 when the need for large amounts of acetone decreased due to the change to the method of incorporation of nitrocellulose in the form of a water slurry instead of dry guncotton, with nitroglycerine.

The biological work of Dr Thysen and Dr Bunker was known across the scientific world and in 1922 they were asked by Alfred Lucas, the chief chemist in the team exploring Tutenkhamun’s tomb, to analyse samples collected in sterilised phials from the tomb which were suspected to possibly contain bacteria causing the unexplained deaths of some of the team. They continued to investigate the microbiology of cellulosic and other textile fibres and their work was eventually transferred to the Chemical Research Laboratory at Teddington in 1933.

The grain store was demolished in 1934 but the cooker house and six of the concrete fermentation vessels remain to this day. The cooker house has gone through many transformations - firstly to a building for the servicing of narrow gauge railway trucks and later to offices, workshops and accommodation for large pieces of testing equipment.

The fermentation vessels were used as refuges at the beginning of WW2 with their large open tops being filled with soil and the lower sections acting as air-raid shelters. Over the past 70 years self-seeded trees have grown in the soil resulting in what must be the largest flowerpots in Dorset.

References:

Bowditch M R Cordite – Poole, a short account of the Royal Naval Cordite Factory

Published in 1983 by MOD

England J C Journal of Naval Science, Volume 18 No 3, August 1992:

Acetone Production at RNCF Holton Heath

England J C The Dorset Year Book 1996 published by The Society of Dorset Men:

Acorns Urgently Needed

England J C Britain at War Magazine, Issue 29 September 2009:

Acorns Urgently Needed