The Story of the

Holton Heath, Dorset, UK

Manufacture of Nitrocellulose - Guncotton

By Dr Bob Dukes

As early as the 1830s it had been found that cellulose could be dissolved in concentrated nitric acid and that the resultant solution poured into water formed a flammable and explosive powder. However this could not be developed into a commercial explosive.

In 1845 Friedrich Schonbein of Basel was experimenting with mixtures of sulphuric and nitric acids when, the story goes, he spilt some acid and mopped it up with his wife’s cotton apron. Having mopped up the offending acid, he hung the apron up to dry over the kitchen stove. Suddenly the apron exploded with a loud bang, fortunately before Frau Schonbein returned to wear the apron. Schonbein called his new material schiessbaumwolle or guncotton and soon established factories to produce it as a replacement for gunpowder.

Unfortunately, guncotton or nitrocellulose, like nitroglycerine can be extremely unstable and a number of the factories were destroyed by explosions, putting Schonbein out of business. Again, like nitroglycerine, the major cause of the instability was residual nitric acid and by the 1860s techniques had been established for removing the excess acid by proper washing, after which guncotton became commercially acceptable.

Later, careful control of the nitration process led to a wide range of materials based on cellulose, including celluloid and rayon.

The terms nitrocellulose and guncotton tend to be used interchangeably but in military terminology guncotton was reserved for material with a nitrogen content of over 13%.

Manufacture

Manufacture of guncotton at RNCF used the Nathan-Thomson displacement method (named after the Superintendent and Manager of the Royal Gunpowder Factory at Waltham Abbey), which was introduced in 1905. Nitration was carried out in earthenware pots one metre diameter and 250mm deep and normally arranged in sets of four as shown in the accompanying sketches.

The pots were connected to supplies of mixed concentrated sulphuric and nitric acids and to water, and were fitted with aluminium hood and fume extraction equipment. The pots had a perforated plate at the bottom (so that about 10% of the volume was below the plate) and in the bottom was a hole for drainage. The whole structure was set up on earthenware columns half a metre high.

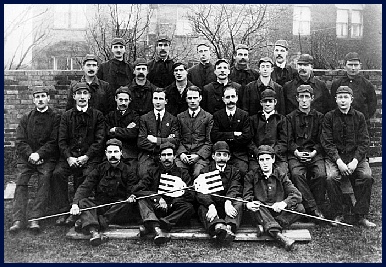

Some 300kg of mixed acids was run into the pot and 10kg of teased and cut cotton waste was introduced a little at a time using aluminium forks to submerge the cotton in the acid. The photograph above of the male guncotton workers from 1918 shows the dipping forks with their long handles to allow the workers to avoid the acid fumes as much as possible.

The nitration process took about two and a half hours and, at the end of this time, the acid was slowly run off and replaced by water. After another three hours the remaining water was allowed to drain through. The guncotton was then boiled in successive quantities of water in an antimony-lead lined wooden vat, some two metres high and three metres in diameter, equipped with steam heating coils. Fifty-one such vats were installed at RNCF and this was a crucial process in removing residual traces of acid which could otherwise result in an unstable material.

Please mouse over

graphic to enlarge

After boiling, the gun cotton was pulped in machines consisting of rotating rollers with knives, which passed between similar fixed knives on the machine bed. The material was then passed, in the form of a slurry, over a grit trap and a magnet to remove any possible contaminants.

The guncotton was then thoroughly washed again in “poachers” or “potchers” equipped with paddles to agitate the aqueous solution. The guncotton was allowed to settle and the wash-water skimmed off. At this point several different batches of

guncotton were combined to ensure a uniform and reproducible product with a nitrogen content of 13%.

The final operation was drying, first in centrifugal dryers and then in drying stoves. These were lightweight buildings where air drawn over steam pipes to raise its temperature to 60 degrees C was blown over the guncotton and the moisture laden air was vented at the bottom.

Cotton was used as a basic raw material from the opening of the factory - the first batch of guncotton was produced on 6 th August 1916 - until 1929 when shredded paper was used as a source of cellulose. Although this was used for several years, it was never completely satisfactory as the shredded paper often packed together so as to limit the area in direct contact with the acid mixture.

The solution to this problem was pioneered by Dr R S G Knight at RNCF. He developed winding rolls of paper together, one straight and the other crimped so

that the final effect was of a roll of corrugated cardboard. All the paper was more easily exposed to the acid and it also did away with the old dipping forks so the work was a little less hazardous.

The paper was delivered in rolls 200mm wide and weighing some 20kg. Considerable quantities were used, in World War II in excess of 2000 tonnes per annum, and it was sourced from various papermakers, although one particular maker of paper was preferred for the crimped sheet. Paper from various manufacturers was colour coded for identification.

The galleries of pictures show the cotton teasing and drying equipment used in the early days and a series showing the nitration of paper and, finally, the processes following nitration.